Open Positions and Thesis Topics

- Studies of patchy/Janus particles self-assembly (suitable for someone with background in chemistry, physics)

- Studies of the optical properties of single plasmonic particles (suitable for someone with a background in physics/applied physics/materials science)

If you have specific experience in any of these areas we would be very interested to discuss a possible position in our group. We welcome speculative applications provided a clear academic and preferably research background in related fields (chemistry, materials science, nanotechnology, chemical engineering etc.) exist. If you are interested in interdisciplinary research combining colloidal synthesis of complex multifunctional nanoparticulate materials, morphological and functional characterisation as well as exploitation in application-relevant systems please send a resume (with publication list, if applicable) and a list of references to robin.klupp.taylor (at) lfg.fau.de

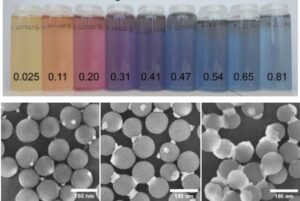

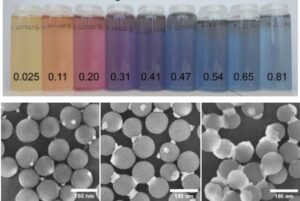

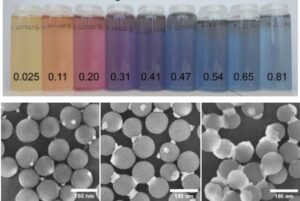

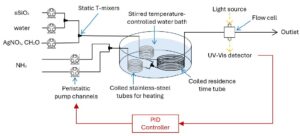

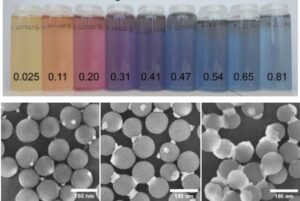

Anisotrope Partikel stehen im Mittelpunkt des Forschungsinteresses der Gruppe Nanostrukturierte Partikel. In den letzten Jahren haben wir verschiedene Methoden entwickelt, um so genannte Patchy Particles zu synthetisieren. Diese Partikel bestehen aus einem dielektrischen Kernpartikel, welches zum Teil mit einem anderen Material beschichtet ist, in unserem Fall mit Edelmetallen wie beispielsweise Silber. Aufgrund ihrer Größe im nm-Bereich weisen die Metallpatches eine Plasmonenresonanz auf, die je nach Form und Größe der Patches zu unterschiedlichen Farben führt (siehe Abbildung 1). Für unsere Patchy Particles haben wir eine äußerst gut steuerbare, kontinuierliche Synthesemethode entwickelt, bei der ein Seeded-Growth Verfahren zum Einsatz kommt. Dadurch kann das Volumen der produzierten Patchy Particle leicht hochskaliert werden. Aufgrund der umfangreichen Anpassbarkeit der optischen Eigenschaften ist das System der Silber Patchy Particles für Farbanwendungen wie Pigmente sehr interessant. Das Ziel dieses Projekts ist es, den Einfluss der verwendeten Keime auf die finale Form der Silberpatches und damit auf die optischen Eigenschaften zu erforschen. In einem zweiten Schritt sollen Patchy Particles als Pigment in einen Polymerfilm eingebracht werden.

Ziel der Arbeit

Im Rahmen dieser Bachelorarbeit sollen Patchy Particles mit ausgeprägten Extinktionsmaxima, d. h. einer definierteren Farbe, synthetisiert werden, indem die Dispersität der Patchformen innerhalb einer Probe verringert wird. Ein zu berücksichtigender Aspekt ist die Art der verwendeten Keime, da mögliche Einflüsse durch verschiedene Größe, Form oder Material des Keims noch nicht geklärt sind. Zum Beispiel beeinflusst die Keimgröße wahrscheinlich die endgültige Patchform (siehe Abbildung 2). Daher werden bei dieser Abschlussarbeit verschiedene Keime bei der Patchsynthese verwendet und die resultierenden Patchformen sowie die optischen Eigenschaften untersucht. In einem möglichen zweiten Schritt werden die Patchy Particles mit Poly(butylmethacrylat) vermischt um Farbfilme herzustellen. Aufgrund des dichroitischen Effekts der plasmonischen Partikel müssen verschiedene Parameter wie Filmdicke und Partikelkonzentration angepasst werden, um den vielversprechendsten Farbeffekt zu erzielen. Das Projekt umfasst sowohl die Partikelsynthese als auch die Charakterisierung durch Spektroskopie und Elektronenmikroskopie.

Contact: Monika Stadelmaier

Anisotropic particles are the focus of the research interest in the Nanostructured Particles Group. In recent years, we have developed various methods to synthesize so-called patchy particles. These particles consist of a dielectric core particle, partially coated with another material, in our case noble metals such as silver. Due to their size in the nm-range, the metal patches exhibit a plasmon resonance resulting in differently coloured samples depending on the shape and size of the patches (see Figure 1). For our patchy particles, we have developed a highly tunable, continuous flow synthesis using a seeded-growth method. This allows us to easily scale-up the volume of patchy particle products. Due to the wide tunability of the optical properties, the silver patchy particle system is highly interesting for color applications as in pigments. The goal of this project is to explore the influence of the seeds used in our method on the shape of the silver patches and thus on the resulting optical properties and in a possible second step the transfer of patchy particles into a polymer film as pigments.

Objective

The objective of this lab-based Bachelor’s Project is to synthesize patchy particles with more narrow extinction peaks, i.e. a more defined colour, by reducing the dispersity of the patch shapes in one sample. One aspect to consider is the type of seeds used in the process, since possible influences of varying seed size, shape or material are not yet determined. It is probable that the for example seed size affects the final patch shape (see Figure 2). For this purpose, the seed types are to be varied throughout the experiments of this thesis and the resulting patch morphologies as well as the optical properties monitored. In a possible second step, the synthesized patchy particles are to be mixed with poly(butylmethacrylate) to produce coloured polymer films. Due to the dichroic effect of the plasmonic particles, several parameters as film thickness and particle concentration have to be adjusted to generate the most promising colour effect. The project will include both particle synthesis and characterization by spectroscopy and electron microscopy. Previous experience of working in a laboratory or with particles are of advantage.

Contact: Monika Stadelmaier

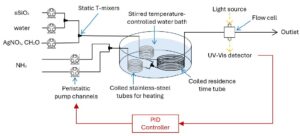

Anisotrope Partikel stehen im Mittelpunkt des Forschungsinteresses der Gruppe Nanostrukturierte Partikel. In den letzten Jahren haben wir verschiedene Methoden entwickelt, um so genannte Patchy Particles zu synthetisieren. Diese Partikel bestehen aus einem dielektrischen Kernpartikel, welches zum Teil mit einem anderen Material beschichtet ist, in unserem Fall mit Edelmetallen wie beispielsweise Silber. Aufgrund ihrer Größe im nm-Bereich weisen die Metallpatches eine Plasmonenresonanz auf, die je nach Form und Größe der Patches zu unterschiedlichen Farben führt (siehe Abbildung 1). Plasmonische Partikel sind vielversprechend in ihrer Verwendung in der Sensorik, Photokatalyse oder Medizin. Allerdings werden diese Anwendungen durch eine limitierte Reproduzierbarkeit und Scale-up der Partikelsynthese beschränkt. Für unsere Patchy Particles haben wir eine äußerst gut steuerbare, kontinuierliche Synthesemethode entwickelt. Dadurch kann das Volumen der produzierten Patchy Particle leicht hochskaliert werden. Das Ziel dieses Projekts ist die erfolgreiche Automatisierung des Versuchsaufbaus wodurch eine genauere Kontrolle der optischen Eigenschaften der Patchy Particles ermöglicht wird.

Objective

In dieser Masterarbeit soll ein geschlossener Regelkreis zur besseren Einstellung der optischen Eigenschaften der Patchy Particles während ihrer Synthese implementiert werden (siehe Abbildung 2). Dies ist besonders wichtig im Falle einer hochskalierten Patchy Particle Synthese, da die Alterung der Reagenzien während des Experiments eine Veränderung der optischen Eigenschaften mit sich bringt. Um die Synthese zu automatisieren, muss der derzeitige Aufbau für die kontinuierliche Synthese so angepasst werden, dass die Reagenzienkonzentration während eines Experiments variiert werden kann. Außerdem muss die Rückkopplungsregelung des automatisierten Aufbaus unter Verwendung von Labview und Python programmiert und getestet werden. Das Projekt umfasst die Synthese von Partikeln, die Charakterisierung durch Spektroskopie und Elektronenmikroskopie sowie die Programmierung der Rückkopplungssteuerung.

Contact: Monika Stadelmaier

Anisotropic particles are the focus of the research interest in the Nanostructured Particles Group. In recent years, we have developed various methods to synthesize so-called patchy particles. These particles consist of a dielectric core particle, partially coated with another material, in our case noble metals such as silver. Due to their size in the nm-range, the metal patches exhibit a plasmon resonance resulting in differently coloured samples depending on the shape and size of the patches (see Figure 1). Plasmonic particles are promising in their use as sensors, photocatalysts or in medical applications. However, the limiting factor for their application is the reproducibility and scale-up of standard synthesis. For our patchy particles, we have developed a highly tunable, continuous flow synthesis. This allows us to easily scale-up the volume of patchy particle products. The goal of this project is the successful automation of the setup and enabling more accurate control of the patchy particles’ optical properties.

Objective

The objective of this project is the implementation of closed loop feedback control in the patch growth for improved control of the patchy particles’ optical properties during their synthesis (see Figure 2). This is especially important in the case of scaled-up patchy particle synthesis since the ageing of the reagents during the experiment results in changing optical properties. For automation of the setup, the current continuous flow synthesis setup has to be adjusted to allow reagent concentration variation during an experiment. Additionally, the feedback control of the automated setup has to be programmed using Labview and Python and subsequently tested experimentally. The project will include particle synthesis, characterisation by spectroscopy and electron microscopy as well as programming the feedback control.

Contact: Monika Stadelmaier

Contact: Robin Klupp Taylor

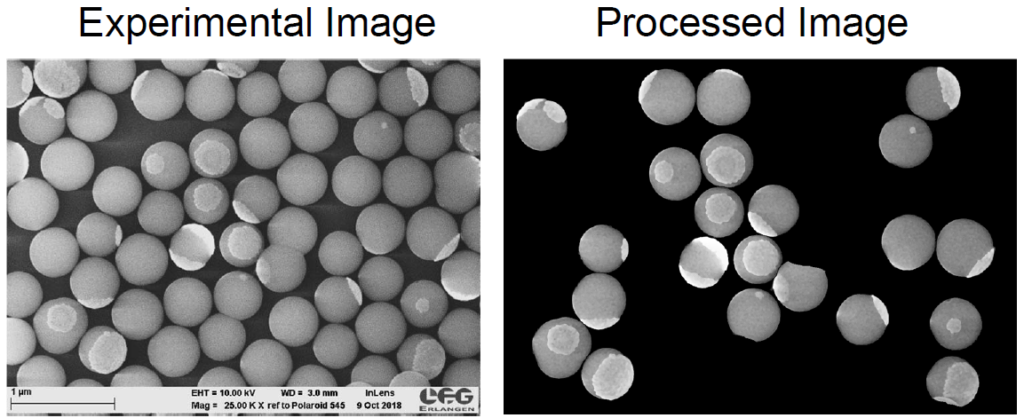

The nanostructured particles research group has developed a simple and scalable process to produce metal patches on core particles. Due to the nature of the processes, the patches have a size distribution and not all core particles get coated (see left image below). In order to further optimize the process to produce patchy particles with desirable properties quantitative insight into the patchy dispersity is required. In this project image analysis will be developed for this purpose. The project involves little or no practical labwork and is particularly suitable for students with some programming experience.

What we want: Image analysis codes to determine core size distribution, patch yield (fraction of particles with patch), thickness and coverage distribution

Starting point: real and simulated images of patchy particles and a code to determine which particles have a patch (see right image below)

Project objectives:

- Develop code able to segment and measure the core particle and patches.

- Develop an experimental protocol for obtaining well dispersed patchy particles, automatically acquiring images on the SEM and analysing them for patch yield and coverage

Tools:

- ImageJ

- Python

- POVRay

- Matlab

- Scanning electron microscopy

- Analytical (ultra)centrifugation

Contact: Robin Klupp Taylor

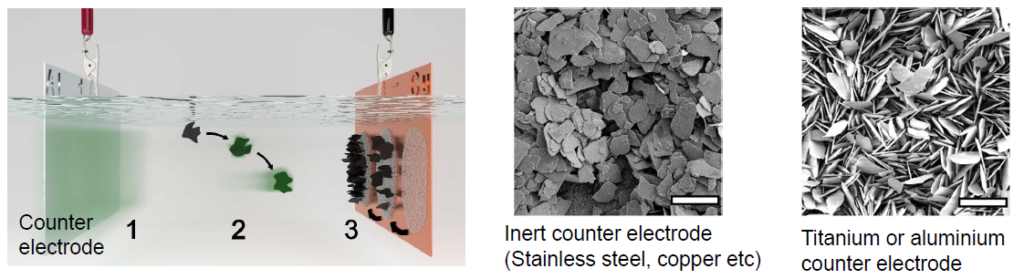

The starting point of this project will be a simple and robust process based on electrophoretic deposition (see Figure below) developed in the group. This process deposits flake-like particles (e.g. commercial mica powder) in an out-of-plane arrangement. In this project, the possibility to arrange flakes in this way will be exploited in order to partially coat the flakes i.e. produce “Janus flakes”. This will be achieved by masking the part of the flakes closest to the substrate with a suitable polymer, followed by coating of the exposed part of the flakes. Once the flakes are released, such partial coating could be used to give the flakes amphiphilic properties, enable catalytic self-propulsion or introduce an unusual optical or magnetic properties.

Project objective: Demonstrate that the out-of-plane oriented flakes can be further processed to produce novel functional particulate materials

- Re-commission previously established electrophoresis setup

- Establish desirable coating chemistry (polymer or inorganic material) on suspended flakes

- Establish partial flake masking strategy (already in literature for spherical particles)

- Show that coating chemistry can be applied to exposed parts of flakes

- Release flakes and characterise properties.

Tools:

- Electrophoretic deposition

- Particle coating methods (wet chemical synthesis)

- Thin film coating methods (spin-coating etc)

- Particle characterisation (DLS, analytical centrifugation)

- Optical microscopy and Scanning electron microscopy